The end of one-size-fits-all battery capacity approach for lift trucks. Learn how to customize OneCharge Li-ion battery capacity for your specific application!

In this episode of his video blog, Water Hyatt explains why opting for lithium-ion can mean more flexibility in battery capacity in your truck.

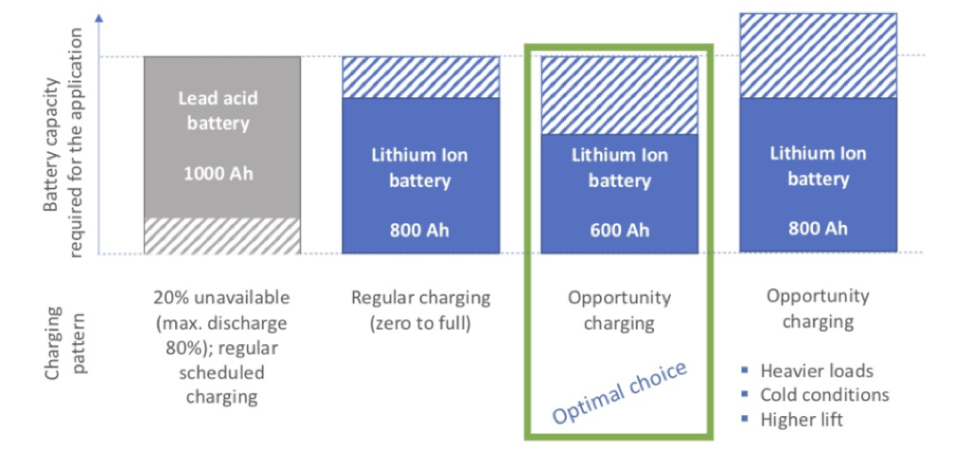

This is how it works: if you had a 1,000 Amper/hour lead acid battery then an 800 amp hour Li-ion battery can do the same job.

The lead acid battery does not go below the last 20 percent and loses voltage dramatically with discharge.

But the Li-ion battery does not show any voltage drop until full discharge!

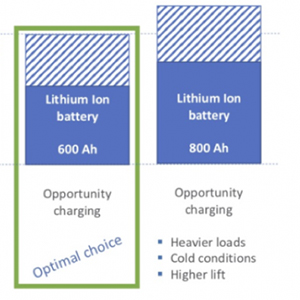

And if you opportunity charge your Li-ion battery at regular 15-minute breaks, then only a 600 amp-hour capacity battery can do the same job. That’s a 40 percent reduction!

What else should you consider?

Apart from the lift truck make, model and voltage we can help you factor in the following when making a selection:

- The truck compartment size, lift height and weight being handled.

- Attachments in use.

- Length of the run, number of shifts and length of breaks.

We recommend a higher capacity for batteries that will be used in cold conditions for the handling of heavy loads and higher lifts.

OneCharge offers over 450 models of Li-ion batteries for nearly every make and model of industrial trucks.

Whatever kind of work you are performing with your truck, OneCharge has a battery suited for your specific application with just the capacity you need.

by Maxim Khabur | November 8, 2019

by Maxim Khabur | November 8, 2019