This is an update on our earlier post on the proposed Zero-Emission Forklift Regulation in California. Please scroll down to read the full article.

The first draft of the Regulation was released in February, but several changes have been made. This regulation will stop the sale and purchase of internal combustion engine (ICE) forklifts in California. Here’s a quick summary of the changes that have been made.

Executive Summary:

- The capping provision limits Class IV forklifts to a minimum of 25% turnover for the first four years.

- The capping provision also limits Class V forklifts to a minimum of 15% turnover for the first six years.

- The phase-out period for Class IV was reduced from 13 years to 10 years.

- The start of the phase-out period for small Class V fleets (25 or fewer) was pushed back to 2029.

- Reporting requirements are reduced.

- Rental agencies will follow the same phase-out.

- Fleets renting forklifts are no longer subject to a 30-day annual limit

- Individual transactions do not need to be reported to the California Air Resources Board.

Updated Phase-Out Schedules for Class IV and Class V Forklifts and Rental Agencies

A capping provision was added to the regulation. Given the short time before the phase-out starts, it was agreed that a limit on how quickly a fleet must turn over its equipment was needed. For that reason, companies are only required to turn over a minimum of 25% of their Class IV forklifts during the first four years of the regulation’s phase-out. At the same time, the requirement for Class V forklifts was amended to a minimum of 15% per year over the first six years of the phase-out. This provides businesses with more time to make the change and to decide on a range of issues, such as the type of forklift batteries that should be used in their new zero-emission forklift fleet.

Despite these caps on a company’s turnover rate, the overall phase-out timeframe for Class IV ICE forklifts was reduced. Instead of having 13 years to make the change to a zero-emission forklift fleet complete, companies must make the change in only 10 years. For small fleets, defined as 25 Class V ICE forklifts or fewer, the phase-out start has been pushed back by three years to 2029. This is to benefit smaller companies that may have a harder time making the transition. In addition, overall, the reporting requirements for the transition have been reduced, making it easier for companies to handle the change without having to do as much paperwork.

The provisions set in place for rental agencies have also been changed so that these entities will now be required to follow the same phase-out schedules as fleet operators. However, fleets that rent forklifts are no longer subject to the prior 30-day annual limit, and rental agencies will no longer have to report individual transactions to the California Air Resources Board.

This changeover has many companies asking questions about zero-emission forklift options. What are the best forklift battery types? Should they invest in maintenance-free lithium-ion forklift batteries? What’s the right battery for their use? What are the main trade-offs between battery types? Are you wondering how to choose lithium forklift batteries? Check out the OneCharge News and Blog page to learn more.

The original article was published on June 7th.

The California Air Resources Board (CARB) is planning to ban sales of all new forklifts that aren’t zero-emission by 2026. Its recent proposal to phase out non-zero-emission forklifts is still in development, and the legislation is not yet in effect. However, the users of the material handling equipment (MHE) industries are questioning what it will mean for their operations—and not just in California, but all over the country.

At its core, the planned proposal would force users to phase out internal combustion forklifts, including propane and diesel forklifts, and instead lease or buy zero-emission material handling equipment.

Starting in 2026, fleets may not purchase large spark-ignition (LSI) forklifts (another name that CARB uses for lift trucks powered by internal combustion (IC) engines) while after 2026 fleets will need to retire existing LSI forklifts that are 13 years old or older. Understandably, fleets will need to plan ahead to guarantee they’re able to meet these regulations.

At OneCharge Lithium Batteries, we always work with our customers to better understand the equipment requirements of their operations. Below, we’ll break down what these new regulations mean, and how they’ll affect different fleet types. We hope this information will simplify planning and help electric forklift buyers adjust to the upcoming mandates.

What It All Means

The new regulation will naturally mean an increase in reporting requirements for fleets and fleet owners, including an initial report with basic company and forklift information, and a final report to be completed when the fleet has fully transitioned to zero-emission lift trucks.

Beginning in 2026, applicable forklifts that are bought or leased will need to be zero-emission, and the phaseout of older, non-compliant models will also begin that year. Starting in 2026, IC engine-powered forklifts that are 13 years old or older, or have an engine that is 13 years old or older, will no longer be allowed to operate.

Not all forklifts will be affected by the regulation. The main segment targeted by the regulation will be large spark-ignition forklifts with a lift capacity of 12,000 pounds or less. Forklifts that won’t be affected include rough-terrain forklifts, pallet jacks, military tactical vehicles, forklifts with telescoping booms, and forklifts owned or operated by facilities that are subject to the Regulation for Mobile Cargo Handling Equipment at Ports and Intermodal Rail Yards.

In 2022, the production of material handling equipment (MHE) struggles to catch up with the demand, owing in many ways to pandemic-related supply-chain issues. How these production issues will affect the adoption of the new regulations remains to be seen, though leading lithium battery manufacturers are already preparing to ramp up production and satisfy the demand for zero-emission forklift batteries.

To make the transition less difficult, there are several exemptions and allowances built into the regulation, including a rental allowance for fleet operators. As long as their intention is reported in advance, fleets will be allowed to rent LSI forklifts for unexpected occurrences or seasonal workload increases for up to 30 days each calendar year.

Similarly, a low-use exemption will allow fleets to keep a number of LSI forklifts as long as they’re used fewer than 200 hours per calendar year. The number of low-use LSI forklifts a fleet can keep will be limited to 10% of its total units. Notably, microbusinesses, which have fewer than 25 employees and less than $5 million in annual gross receipts, will be allowed to keep one low-use LSI forklift indefinitely.

What will these regulations look like in reality, and how could they potentially affect real-world fleets? To make the regulation’s implications clearer for our readers, we’ve put together a few scenarios that highlight how the regulation will play out for different types of fleets.

Zero-emission Forklift Fleet Transition

Company 1

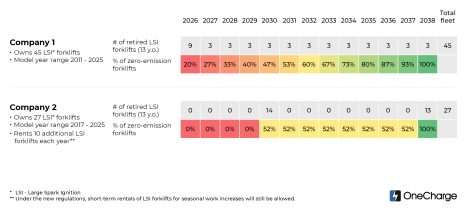

In our first scenario, the fleet has 45 large spark-ignition (LSI) forklifts. In 2026, our starting year, the model years of their forklifts range from 2011 to 2025, meaning their forklifts are all between one and 15 years old.

Starting in 2026, additions and voluntary replacements would be required by the new zero-emission regulations. In that first year, the fleet would have nine forklifts from the model year 2013 or earlier—which means, essentially, they would have to replace nine forklifts.

For every following year, three of their remaining forklifts would become older than 13 years and would need to be replaced. That doesn’t sound too difficult, and keep in mind that the fleet would be allowed to keep five low-use LSI forklifts of any model year until 2031.

Company 2

This hypothetical fleet has 27 LSI forklifts, from model years 2017–2025. However, the model years aren’t evenly spaced for this fleet: 14 of the forklifts are from model year 2017, and 13 are from model year 2025. Additionally, this fleet experiences extra business in December, and typically rents 10 extra forklifts for the month.

Because this fleet’s forklifts are concentrated in specific model years, there will be long stretches of time when they don’t need to retire any units. Between 2026 and 2029, no turnover will be required, and the same is true of the period between 2031 and 2037. However, in 2030, 14 of their model year 2017 units will need to be replaced, while in 2038, 13 of their model year 2025 units will need to be replaced.

Smart planning will be required in a situation like this. The good news is that under the new regulations, short-term rentals of LSI forklifts for seasonal work increases will still be allowed. In addition, this fleet would be able to keep three low-use LSI forklifts of any age until 2031.

by Maxim Khabur | Julho 26, 2022

by Maxim Khabur | Julho 26, 2022